The classic Katherm QK is now supplemented by Katherm QK nano

The incentive for nano came from London: here, as in many export markets, the floor construction height varies between 400 millimetres in commercial buildings and merely 100 millimetres in residential buildings. This makes different demands in the construction heights of trench heating units. Even in this country, the floor construction height is becoming more and more an issue for construction planning. After all, the less the respective ceiling depth is, the greater the requirement for a low trench heating. With the Katherm QK nano, Kampmann has now created the perfect complement to the classic Katherm QK.

The two letters QK have what it takes word-wise. QK stands for “Querstromventilator Konvektion” (cross-flow fan), the technical heart of the Katherm QK tried and tested for almost 2 decades. The technical and physical quality of the trench heating system have made it an extremely popular top seller amongst planners worldwide. With a trench height of 112 millimetres, it perfectly fulfils the space requirements of modern indoor climates, especially with large floor-to-ceiling window surfaces: yesterday, today, tomorrow.

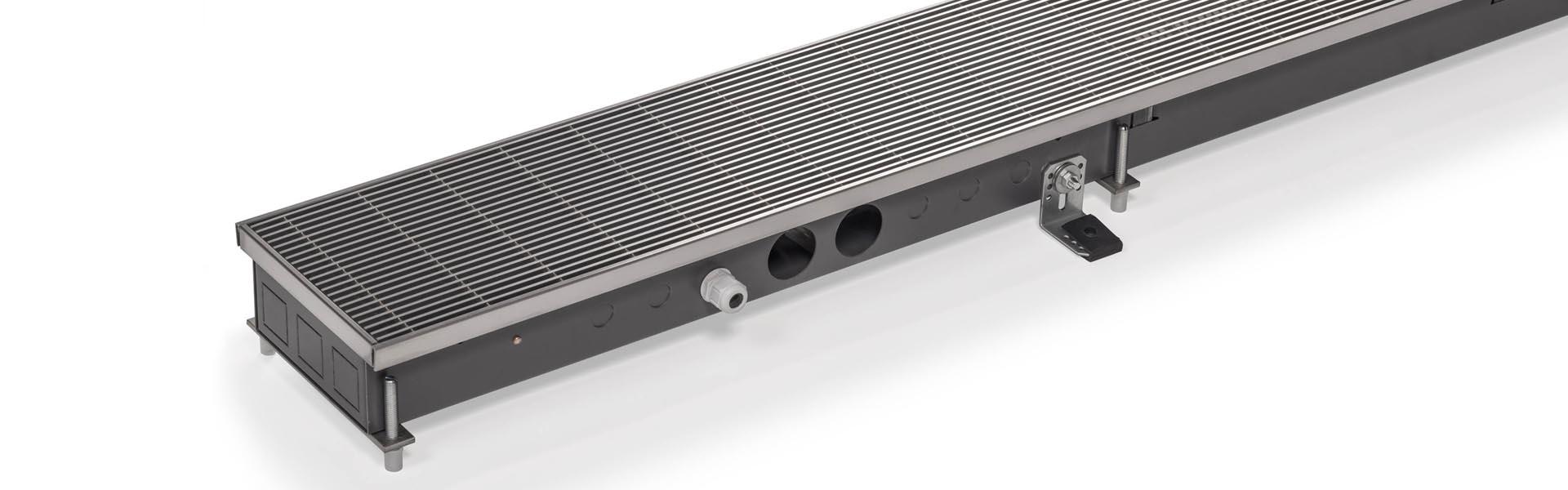

With the Katherm QK nano, Kampmann now places an addition to the tried and tested classic in the portfolio of their trench heating units. The physical difference lies in the small suffix: On the outside, the trench height and trench width, on the inside the fan and the heat exchanger are smaller. Specifically: in comparison to the QK, the trench height of the QK nano has been reduced from 122 millimetres to 70 millimetres, a saving in the required trench construction of 42 millimetres. For planners, the potentially possible reduction in the floor construction in one-storey or multi-storey projects of great relevance and attractiveness!

Furthermore, in addition to the Katherm QK with its three trench widths of 182, 207 and 232 millimetres, with the Katherm QK nano and its trench width of 165 millimetres, the development of a fourth, extremely slim version of the trench heating has been successful. It comes up with further nano parameters, for example the innovative FineLine steel grille. The combination of narrow width of the QK nano, the grille structure and the numerous different colours of the FineLine grille make it the perfect aesthetic and individual addition to modern construction projects, especially in residential, office and administration buildings as well as hotels. In addition, the depth of the frame edge was reduced by more than half from 18 millimetres in the QK to 8 millimetres in the nano version. In technical terms, the Kampmann developers succeeded in fully achieving the technical efficiency of the Katherm QK despite the significant reduction in the physical properties: “Even though the fan and the heat exchanger are smaller in the QK nano, we succeeded in achieving a performance boost by way of a clever layout that makes the QK nano fully comparable with the QK in terms of performance”, says the product manager Marcel Rakers. He is convinced by Kampmann having created a high quality design, the familiar Kampmann quality and the innovation of generating the same amount of performance with significantly less space. The youngest member of the Katherm QK family has already been awarded the Plus X Award, not once but three times in precisely these categories - high quality, design and functionality.

The new Katherm QK nano feels particularly at home where rooms and ceiling have been planned to their maximum efficiency and aesthetically. Thanks to the combination of quiet EC cross-flow fan and high-performance convector, it caters for an optimal room climate. Many variations as well as extensive accessories predestine the latest Kampman trench heating for large office complexes. The nano solution is the ideal supplement to the Katherm QK family!

KATHERM QK NANO:

• smallest of dimensions promise maximum use of the room volume

• innovative, filigree FineLine grille with matching frame edge for the perfect look

• available: 24 V control unit, electromechanics control unit or KaControl control unit

• Integration in KaControl networks or building automation systems such as KNX, Modbus or LON are possible